Price 28000.00 आईएनआर/ टुकड़ा

MOQ : 1 टुकड़ा

Specification

- कम्प्यूटरीकृत

- स्वचालित ग्रेड

- कंट्रोल सिस्टम

- वोल्टेज

- वोल्ट (v)

- रंग

About

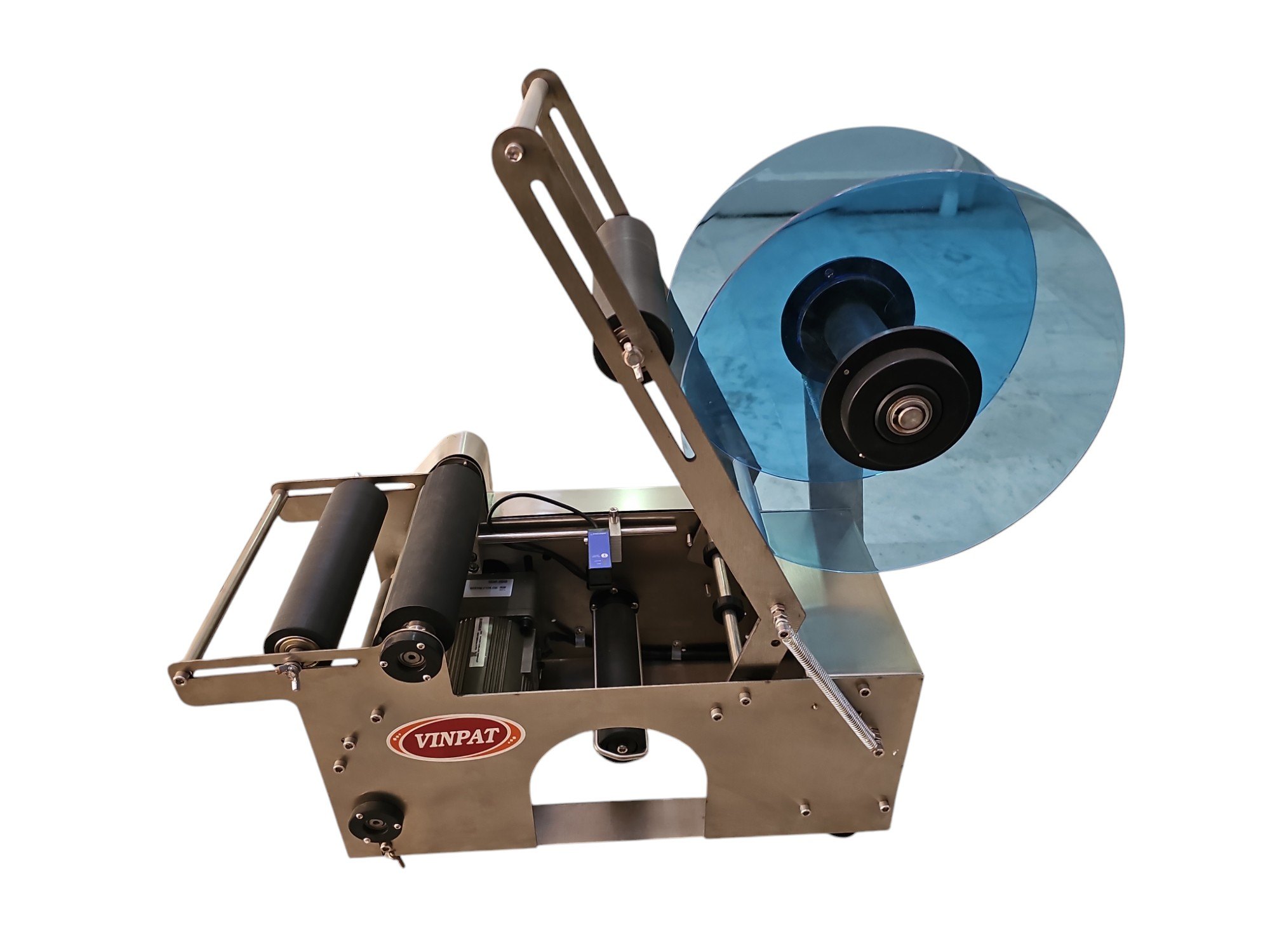

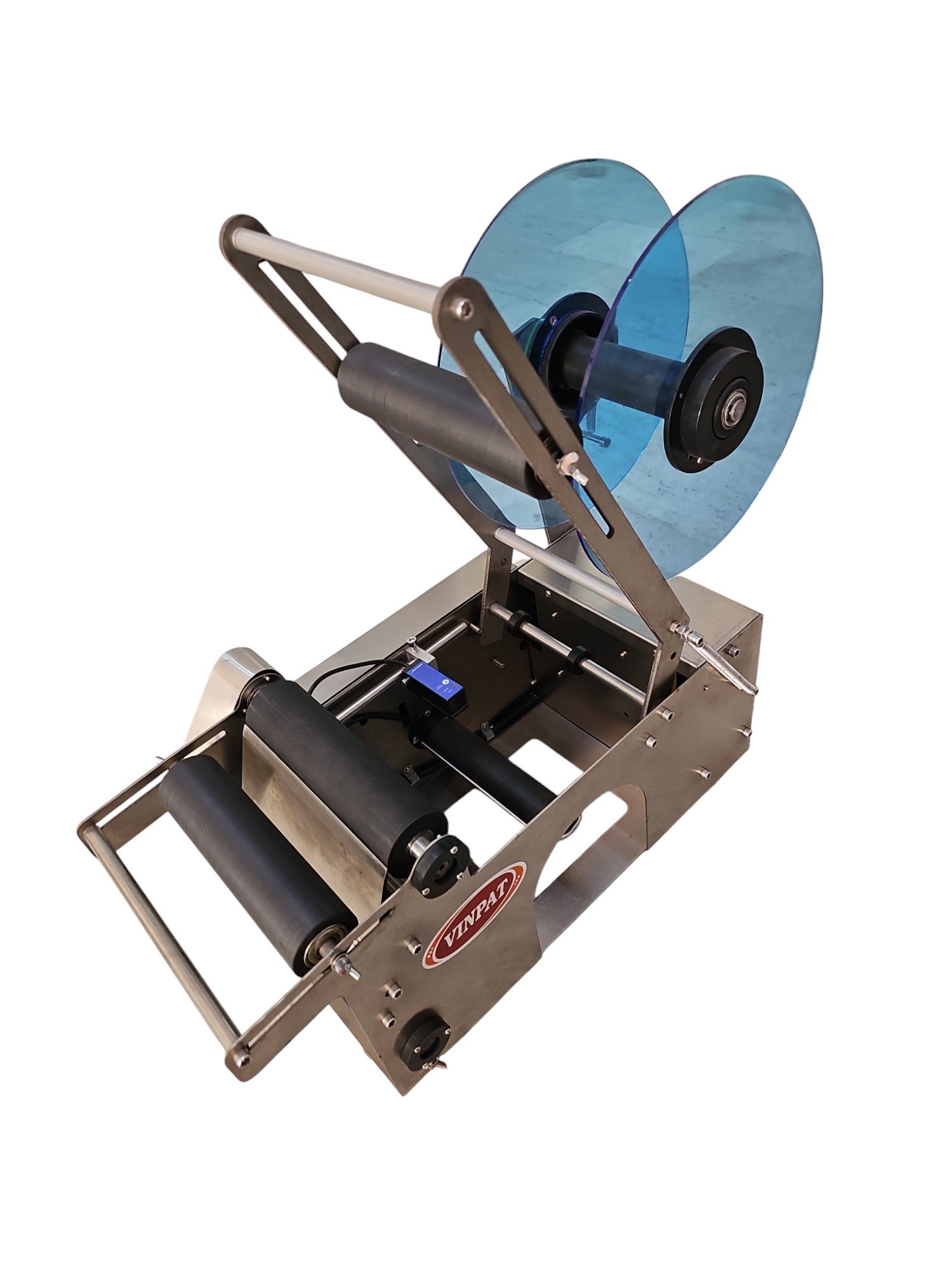

ROUND BOTTLE LABELLING MACHINESpecification/Additional Details

Advanced PLC Control for Superior Accuracy

Equipped with a sophisticated PLC Control system, the Bottle Labeling Machine delivers exceptional precision and repeatability in label placement. This technology reduces the risk of labeling errors, helps minimize downtime, and contributes to a streamlined packaging process. Its computerized interface offers user-friendly operation and easy customization for different label sizes and bottle types.

Fully Automatic Operation for Maximum Efficiency

This machines automatic grade ensures that bottles are labeled rapidly and consistently without manual handling. The automated process is ideal for medium to large-scale operations looking to increase throughput while maintaining quality. The 220 Volt power supply ensures compatibility with standard Indian electrical systems, making installation and maintenance straightforward.

FAQs of Bottle Labeling Machine:

Q: How does the Bottle Labeling Machine work with different bottle sizes and shapes?

A: The machine is designed to handle various bottle sizes and shapes through adjustable settings on its computerized PLC Control system. Operators can easily program different parameters to ensure accurate label application regardless of the bottles dimensions.Q: What are the main benefits of using a computerized, automatic bottle labeling machine?

A: With its computerized and automatic functions, this machine boosts labeling speed, ensures consistent quality, and minimizes operator intervention. It not only enhances productivity but also reduces the chances of human error, ultimately leading to cost savings and improved product presentation.Q: Where is this Bottle Labeling Machine typically installed and used?

A: This machine is commonly installed in manufacturing plants, bottling facilities, and packaging units across India. It is suitable for industries such as food and beverages, pharmaceuticals, and cosmetics, where efficient and accurate labeling is essential.Q: When should you consider upgrading to an automatic labeling system like this one?

A: An upgrade is ideal when your manual labeling process can no longer keep pace with production demands, or if you require improved consistency and tracking for regulatory compliance or brand enhancement. Automation becomes especially valuable as production scales up.Q: What is involved in the setup process of this labeling machine?

A: Installation involves placing the machine on a stable surface, connecting it to a 220 Volt power source, and configuring the PLC system with bottle and label specifications. Manufacturers or suppliers typically offer onboarding support and training for smooth setup.Q: How do users operate and manage the machine for daily production needs?

A: Operators use the intuitive computerized controls to select and adjust settings based on the batch requirements. Routine tasks include loading labels and bottles, monitoring the process, and periodic maintenance to ensure reliable operation.

Tell us about your requirement

Price: Â

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

मोबाइल number

Email

अधिक Products in बोतल कैपिंग मशीन Category

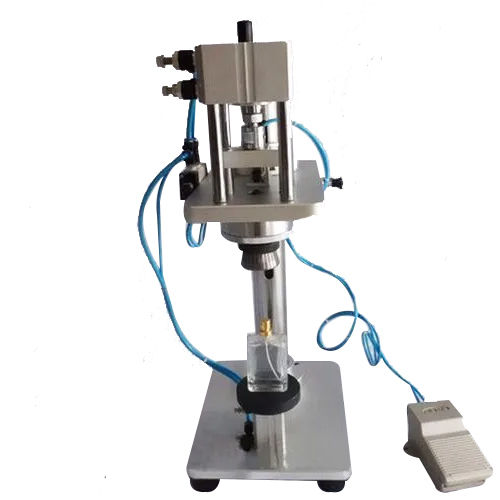

औद्योगिक बोतल कैपिंग मशीन

फ़ीचर : टिकाऊ

मूल्य या मूल्य सीमा : आईएनआर

कम्प्यूटरीकृत : नहीं

माप की इकाई : यूनिट/यूनिट

स्वचालित ग्रेड : ऑटोमेटिक

न्यूनतम आदेश मात्रा : 1

जांच भेजें

जांच भेजें

जांच भेजें

जांच भेजें एसएमएस भेजें

एसएमएस भेजें